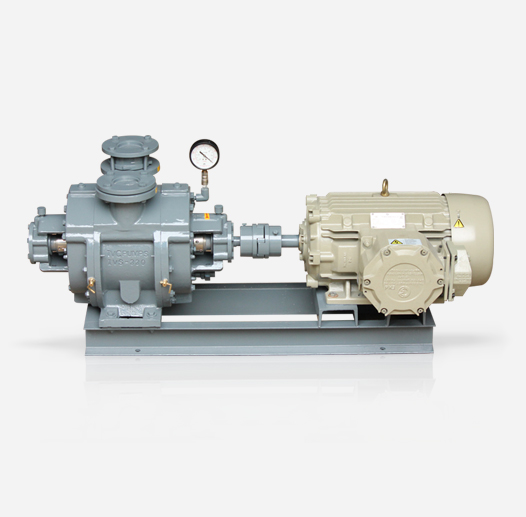

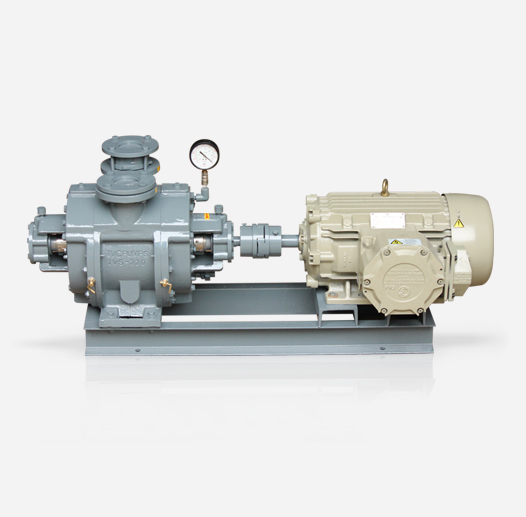

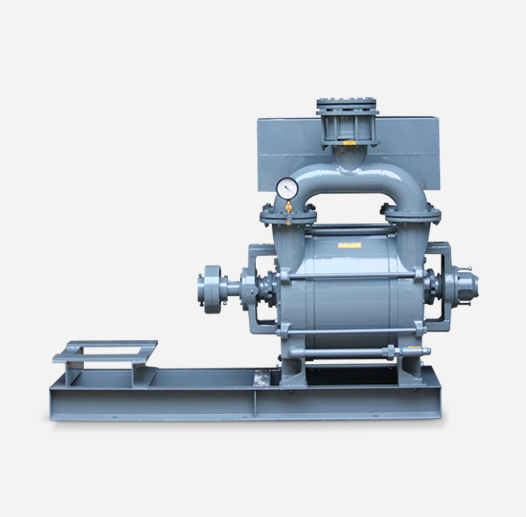

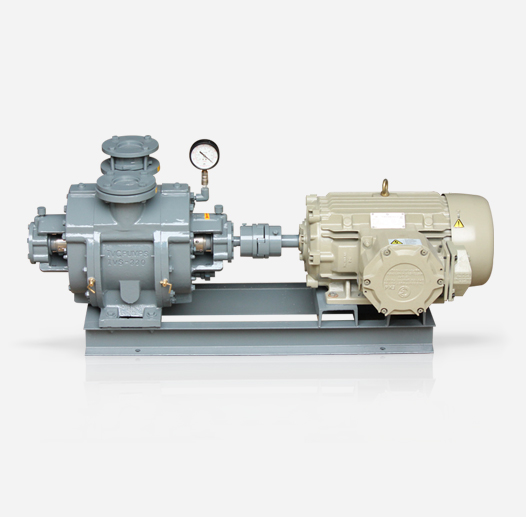

Liquid Ring Compressor

Liquid Rin Compressor Must be Equipped on Pressure Side with Water Separator on which Ring – Liquid id Separate from Conveying Medium. The Liquid Separator is Flitted with Float valve Allowing the seoarated Liquid to escape. Depending on application the ring fluid ca be Re Circulated to the Compressor after Passing a Re Cooling Device. The Non-Return Valve for the Liquid when Conveying is built in to the pressure piping.

When Conveying air, the simplest control to the end pressure is done by means of normal safety valve. For Gases a Closed By Pass Valve must be used when the excess gas return to the suction piping. The fully Automatic control is the most economical whereby the compressor is out of operation according to the pressure pervading on the safety valve.

.jpg)